AQC Dust Collecting Systems Dust Collectors

Fume Arms

Source Capture

For More Information:

Fume extraction arms are a better alternative to overhead hoods where workers were breathing dust and smoke-filled air as it was travelling upward. Source capture is the safe way to eliminate harmful pollutants. From laboratories to large welding shops, MAXAIR will get the job done.

MAXAIR is built to reduce to a minimum the presence of industrial indoor air particles. Our arms are ideal for a whole range of capture applications: smoke, steam, dust, welding, and harmful gases. The highly functional design facilitates fume arm handling and makes shifting easy.

Our articulated fume extration arms can be used with our portable filtration units MAXIROLL, MAXICART and MINIROLL. The MAXIREACH, MAXITOP and MAXIRAIL can also be paired up with the fume arm.

Some of our outstanding standard features :

Our highly functional design facilitates fume arm handling and ease of movement. All supports and articulation joints are outside of the fume arm. The inside is smooth, without any obstacles that could reduce air flow, accumulate deposits and increase internal friction, which consume energy unnecessarily.

External supports and articulation joints are readily accessible, easy to adjust and require no maintenance. The unique design of the robust and durable top pivot made of steel makes the 360° rotation easy.

- No internal joints

- Smooth tubes, low static pressure

- Air volume damper included

- Self-locking joints

- 2 grab handles for arm positioning

- Hood diverter increasing capture velocity

- Shipped fully assembled

- 5 different diameters

- Stainless steel tubes and hood available

Extension Boom

Source Capture

For More Information:

Maxireach extension booms are made of steel with single or double pivot joints. Friction disks at the joints ensurt no steel parts rub against each other causing premature wear. The second pivot works on a ball bearing assembly.

The extension beams are manufactured from heavy gauge steel tubing with a bearing swivel and can also be equipped of a single or a double pivot joint. The MAXIREACH is equiped with high temperature flexible hoses as joints for temperature up to 250oF. In conjunction with their primary function, it can be used to support items such as welding wire feeders, hoses, or cables.

Some of the outstanding standard features:

The extension booms combined with the MAXAIR fume arm, the MAXIREEL hose reels or the MAXIDROP hose drops helps reach areas that are distant from a wall or other mounting areas. The swivel section of MAXIREACH is made of rolled steel pipes. The MAXIREACH is adapted to support a MAXIDRIVE fan or a flanged duct connection.

- Single or double pivot

- Adjustable pressure friction disks

- Ball bearing movement

- Increases reach of equipment by up to 20’ (6,2 m)

- Top or bottom exhaust outlets

- Two diameters available 6’’ (152mm) and 8’’ (204mm)

Exhaust Hose Drop Systems

Source Capture

For More Information:

The MAXIDROP exhaust hose drop system is an interesting alternative to hose reels. It was designed to work with small cars and up to larger diesel engines, MAXIDROP assures that the hoses will not be crushed by workers or vehicles since they are lifted and secured by the balancer. The ratchet lock system on the balancer allows the hose to be pulled at the exact length required. Single, dual or fan equipped systems are also offered with different diameters, lengths and temperature ratings of hoses. MAXIDROP can be used with MAXIREACH extension boom and MAXIRAIL exhaust ducting with trolley system.

Some of our outstanding standard features :

Our balancer ensures the flexible hose does not rest on the floor and risks of being crushed. The MAXIDROP can also be used for removing harsh fumes in tanks or containers. A variety of tailpipe adaptors is also offered depending on the application.

- Easy to use and install

- Small cars to diesel trucks application

- Spring balancer with ratchet lock system

- Multiple hose diameter and temperature options

Exhaust Ducting With Trolley System

Source Capture

For More Information:

The exhaust ducting trolley MAXIRAIL system is designed to draw and remove smoke, gas and dust pollutants from working areas. The sliding trolleys travel easily on casters outside of the rail ensuring that the interior of the rail is smooth and has minimum static pressure.

The rubber lips open and close as the trolley moves along the rail minimizing air loss. The MAXIRAIL can be mounted on ceiling or wall supports according to applications.

It can be fitted with one or more MAXAIR fume arms, MAXIREEL hose reels or MAXIDROP hose drops for vehicle fume extraction.

Some of our outstanding standard features:

Multiple rail segments can be installed end to end. The basic element of the duct is a 6’ (1.8m) segment. Its aluminum construction is optimized to minimize hanging weight.

- Duct and sliding trolley combination

- Multiple segment connection

- Choices of 6’’(152 mm) or 9’’(229 mm) or trolley diameters

- Trolley on ball bearing casters

- Lightweight aluminum construction

- Easy installation

- Welding and fume capture

- Vehicle maintenance shops

- Low ceiling facilities

- Linear or assembly lines

- Ideal for low ceiling facilities

Fumes and Gases Exhaust Hose Reel

Source Capture

For More Information:

Cars and trucks maintenance facilities are often confronted with the presence of fumes and gases produced while the engines are running during tune-ups or repairs. The MAXIREEL exhaust hose reel is well adapted to capture the deadly pollutants emitted from combustion engines. Made of rugged rolled steel components, the MAXIREEL recoils the flexible hose around the drum when the unit is not in use.

A heavy-duty dual spring pack with ratchet lock mechanism is located on the side of the reel. Optional motor driven reels with a radio signal control is also available with a fan mounted directly on the hose reel. A central fan can also be used for multiple reel installations. Fitted directly on the automobile tailpipe or truck stack, the different available nozzles can be made of steel, stainless steel, aluminum, or rubber.

MAXIREEL can be equipped with MAXIREACH single pivot boom.

- Heavy gauge steel construction

- Multiple hose diameters available – 3’’(76 mm), 4’’(102 mm), 5’’(127 mm), 6’’(152 mm) and 8’’(204 mm)

- Heavy duty tempered steel spring pack

- Powder coat painted and galvanized steel components

- High temperature hose (1200 oF (650 oC))

- E.Z. lock ratchet mechanism or motorized operation

- Shipped fully assembled

Exhaust Removal for Fire Stations

Source Capture

For More Information:

MagneGrip – Exhaust removal systems are an automatic disconnection system to insure fast transitions from the start of the engine to the exit of the fire station.

Fully automatic possibility – When the engine starts, a sensor automatically switches on the exhaust fan. All toxic exhaust soot and gases are drawn through a high-temperature sealed ductwork hose and are safely dispersed outside the building. The fan shuts down automatically after a delay.

Always Protected – For engine testing, the manual override option is used to keep the fan on while the engine runs for longer periods. With the Exhaust Removal System connected to the apparatus, firehouse personnel are totally protected from breathing cancer-causing exhaust gases.

Problem-Free – During emergency runs, MagneGrip’s revolutionary, patented nozzle automatically disconnects as the vehicle exits the fire station. No air compressors or electrical system support is required for the system to operate.

More solutions – MagneGrip Group has more exhaust removal solutions than any other company. Don’t settle for the only system a manufacturer offers – compare systems to make the best choice. This provides your fire department with an exacting application and no operational problems.

- The most advanced technology for exhaust removal

- Tested and proven in thousands of applications

- 100 % effective in removing cancer-causing toxins

- Safest and most reliable system available

- Requires less maintenance than any other system

- Easy to use, dependable, fully automatic operation

Industrial Exhaust Fans

Source Capture

For More Information:

The MAXIDRIVE exhaust fan is designed and manufactured with backward inclined metal or aluminum blades to extract smoke, vapor and light dust away from the worker’s breathing zone. The rugged steel housing with aluminum impeller assures a non-sparking device.

Many of AQC’s equipment’s need fans to capture polluted air. The MAXIDRIVE can be mounted directly with MAXAIR fume arms, MAXIREACH extension booms or MAXIREEL hose reels.

A standard backward inclined aluminum impeller delivers sufficient air volume while sustaining low to medium static pressure. AQC also offers steel impeller with protective coating for aggressive applications. Fans can be directly mounted to the equipment, on roofs or hanging from ceilings.

MAXIDRIVE fans use standard TEFC 3500 RPM motors but special motors such as explosion proof are available.

- Multi purpose for source capture

- 3450 RPM direct drive design with TEFC motors

- Adjustable orientation air discharge

- Powder coat painted housing

- Inlet cone for maximum suction

- Wide mesh inlet protective screen

Downdraft Tables

Source Capture

For More Information:

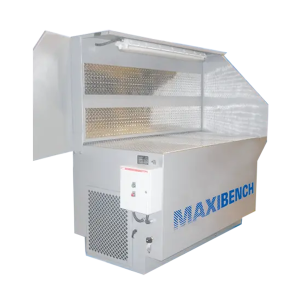

AQC MAXIBENCH is designed for source capture in welding, grinding, sanding, mixing, or woodworking application and provides the user with a clean environment from hazardous volatile dusts and fumes. In compliance with clean air rules and regulations, the MAXIBENCH downdraft tables capture and filter harmful pollutants permitting clean air to be returned into shops and plants. The sophisticated filtration system eliminates expensive cooling or heating costs compared to methods where contaminants are exhausted outside the workplace.

Maintenance of the MAXIBENCH table is reduced to a minimum, dust collector drawers are emptied occasionally, and the cartridges or filters are cleaned by a pulse of air from the integrated tank. Workers spend more valuable time in production than on maintenance downtime. Downdraft benches are an interesting alternative when fume arms are not the solution.

- Water trays spark arresters

- 95% at 0.05 micron efficiency

- Fully welded reinforced 12 gauge steel cabinet

- Easy access removable dust drawers

- Safe downflow source capture.

- Suction option through back wall.

- Two sizes available

- Integrated fan option.

- Self-cleaning by air pulse option.

- Low noise levels.

- Different work surfaces available (rubber, plastic.).

Ceiling Mounted Air Filtration Hose Drops

Source Capture

For More Information:

The MAXITOP is the ideal unit when floor space is limited. Our ceiling mounted air filtration unit is an overhead cartridge dust collector with an automatic cleaning system. The MAXITOP has four easily accessible and removable cartridges which have an efficiency of 99.9% at a size of 1 micron and can hold one or even two MAXAIR arms. It has the option of different CFM’s and recirculation of clean air is possible to save energy and financial resources. The MAXITOP is easy to use and convenient for small shops or tight spaces.

- High efficiency cartridge filters

- Automatic self-cleaning

- Source capture with MAXAIR fume arm or ambient air filtration

- Clean air recirculation

- Dust storage drawers

- Access doors to cartridge

Portable Filtration Units

Source Capture

For More Information:

Source capture is very important when it comes to fumes, gases and dust for the safety of all workers. As we know, manufactures are not small places and sometimes installing a big source capture system is not an option. Therefore, we have created our portable filtration units to cover more ground with smaller units. These units vary in size and strength and can be moved to capture all fumes, gases, and dusts around. Our various options are made for all types of work such as sanding, welding, grinding and much more. Their compact sizes make them easy to work with and they are very efficient.

Here are some details of our portable filtration units. Our MAXILAB unit is specifically for white rooms and pharmaceutical domains where washing down the unit to prevent the spread of particles or hazardous contaminants is a priority. Our MAXICART is a portable unit able to have two arms mounted on its top. It can serve two stations at once while pulling 1500 cfm. Our MAXIROLL is a smaller unit with one arm able to pull up to 650 cfm. Lastly, we have the MINIROLL which is the smallest unit we have. It is the most efficient for its compact size. This unit can pull up to 800 cfm.