Jeremias® Venting Accessories

Barometric Exhaust Dampers

Exhaust Dampers

For More Information:

TYPE MG-1

Gas

A double-acting control for gas-fired furnaces and boilers is widely used for conversion burner installations, gas draft-induced appliance operation with mechanical draft inducers, or sidewall power venters. lt is also recommended for use on gas atmospheric appliances where a draft hood cannot be installed, and can improve combustion stability and draft on many gas atmospheric installations with venting problems.

The MG-1 provides precise, accurate control of drafts at levels higher than permitted by a standard draft diverter, which is a frequent requirement with gas. Because it is double-acting, it opens out to relieve positive vent system pressures as low as .01″. Draft adjustments using weights are simple and accurate from .01” to .1”.

TYPE MG-2

Solid, Oil, Or Gas Commercial/Industrial

This is a series of compact, rugged, heavy-duty controls for use on large residential, commercial, and industrial applications. The Field Type M+MG2 Draft Control provides precise draft regulations for solid fuels, oil, gas, or oil/gas applications requiring only the simplest, on-the-job adjustments depending on which fuel is to be utilized. In a gas installation, the double-acting Type M+MG2 is specified instead of a draft hood to give the appliance the assistance of the chimney. In a duel fuel oil/gas or a gas-fired only application, use the M-MG2 as a double-acting draft control with the optimal Field Thermal Switch accessory.

Use the M+MG2 as a single-acting draft control for oil or solid fuel applications. For any installation with 10″ or larger diameter smoke pipe, specify Jeremias’ standard M+MG2 Draft Control, the unit that can be adapted to any fuel. The moving part (gate) rests on a long, thin, stainless steel knife edge which, in turn, is supported by self-aligning and self-cleaning bearings. When the heavy gauge gate moves, only the knife edge rests on the bearing for minimum friction and maximum sensitivity to draft changes.

Motorized Exhaust Dampers

Exhaust Dampers

For More Information:

MED-GA

Motor actuated gas vent damper for overpressure applications with wet exhaust conditions (Category IV Appliances).

Reduction of cycle venting losses through boilers and draft hoods.

- All-stainless steel construction.

- Heavy duty design.

- Disc is metallic tight to outer casing.

- Overload protected motor.

- Automatic stop.

Purpose:

The damper rod is externally turned by an actuator. The rod is connected to a damper blade that rotates to restrict exhaust flow.

Construction:

All stainless steel construction.

0.03” – 0.06” thick ASTM 316L stainless steel housing.

0.06” thick (14 gauge) ASTM 316L stainless steel blade and stiffener.

0.06” thick (14 gauge) ASTM 316L blade stop (no seal, metal to metal).

Connection / Installation Details:

Connection System: KL coupler system.

Positioning: horizontally or vertically – shaft must remain horizontal.

Also available for appliances with pilot flame.

Classifications:

Temperature: Max. 392°F

Pressure: 0.85” WC

Classifications: ANSI Z21.66-2015, CSA6.14-2015, Class-C330503; Class-C330583

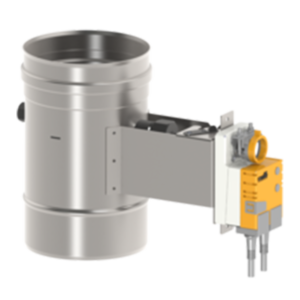

MED-HP

Motorized exhaust damper for High Pressure.

- All-stainless steel construction.

- Heavy duty design

Purpose:

The damper rod is externally turned by an actuator. The rod is connected to a damper blade that rotates to restrict exhaust flow.

Construction:

All stainless steel construction.

0.08” thick (14 gauge) ASTM 316L stainless steel housing.

0.08” thick (14 gauge) ASTM 316L stainless steel blade and stiffener.

0.08” thick (14 gauge) ASTM 316L blade stop (no seal, metal to metal).

0.87” thick Ø shaft with 0.63” square actuator connection.

Mounting plate is a perfect match for Belimo GMX120-3

Actuator (not included).

Two (2) gas tight up to 5000 Pa (20” WC) graphite packing gaskets.

Connection / Installation Details:

Connection System: 1.5” wide flange1.

Positioning: horizontally or vertically – shaft must remain horizontal.

1Standard System (any connecting means are possible, examples: KL, 0.5” rolled flange, etc.)

Classifications:

Temperature class: T400 ” 400°C (752°F)

Pressure class: H1 5000 Pa (20” WC)

Condensate durability: W dry/wet

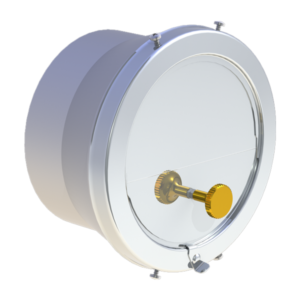

Implosion Relief Valves

Relief Valves

For More Information:

Relief of negative pressure operation in order to assure no flue gases can escape during standard operation.

Implosion relief valve venting accessories are for use in engine exhaust, heating appliances, and other fuel fired equipment.

During normal operation the spring keeps the cover plate closed, if the combustion air damper is closed at the burner due to a blackout, the chimney cannot draw in air through the boiler. The “missing” air now returns through the implosion damper. This prevents the so-called Joukowsky shock by immediately opening the cover plate. Example, if the flue gases are cut off from the chimney during a sudden appliance shutdown, the negative pressure in the chimney may contract (warp) the connecting breeching.

Connection: Flange or factory welded onto a fitting. May be installed vertically or horizontally.

Pressure Relief Valves

Relief Valves

For More Information:

When combustion engines or special gas engines are operating, it is possible that the incompletely combusted fuel mixture gets into the exhaust gas line.

Possible causes: Not tight closing exhaust valves, an incorrect air / fuel ratio, insufficient fuel supply, an incorrect ignition timing or a too rich fuel mixture.

If the unburned fuel mixture ignites because of the glowing hot catalyst, then this would lead to an explosion in the exhaust system. Therefore, the installation of a pressure relief valve (explosion damper) is recommended, especially for large systems. The PRV allows the explosion pressure resulting from the explosion to escape automatically from the system in seconds, thus preventing damage to the exhaust gas line.

Jeremias pressure relief dampers are made of high-quality 316L stainless steel and can be used up to an exhaust gas temperature of 1112 °F (600 °C). Thanks to the variably adjustable opening pressure, the PRV can be adjusted according to the requirement of respective system.

Condensing Boiler Exhaust Dampers

Relief Valves

For More Information:

The VBD Vent Damper System consists of a single blade damper. It can be used as an on/off damper to prevent airflow though the appliance in an off cycle as well as to maintain a constant negative or positive pressure in the vent exhaust connector.

Construction:

20 Gauge 316L stainless steel housing and blade

½” graphite sealed bearings

Viton seal on damper blade

Connection / Installation Details:

½” flanged connections

Positioning: horizontally or vertically – shaft must remain horizontal