SVL News

Jeremias’ DWGD (Double Wall Grease Duct) Line’s Safety Features Will Impress Anyone

Jeremias' UL Listed DWGD's Proven Safety and Efficiency is Outstanding

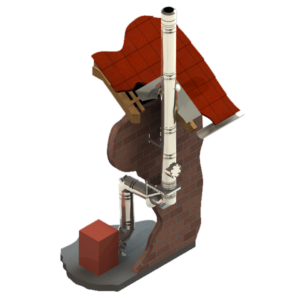

Jeremias, with forty years in the HVAC industry, is one of the leading manufacturers of chimney systems and flues for ventilation and exhaust gases. It has products that fit your commercial, industrial, and residential needs. In addition to offering over 90 advanced UL listed products and specializing in double walled grease ducts, Jeremias products also provide high quality and efficiency unlike any other.

Exceptional Fire Protection for Challenging Applications

Kitchens, labs, manufacturing plants, oil refineries, and other sites that work with oil have an increased risk of potential fires. Jeremias has a line of grease duct (GD) proven to beat the competition for exceptional fire protection and durability. The DWGD (Double Walled Grease Duct) withstands 500 degrees F sustained internal temperature, and 30 minutes at 2000 degrees F, simulating a grease fire. DWGD reduces the risk of grease fires while maintaining its integrity. Leakage testing was also done with refined pork lard and water, as well as 90″ W.C. of pressure testing. Jeremias also has the DWGD-ZC (zero clearance), designed to provide a safe option for tight spaces where the duct has to be near or against appliances and walls.

UL Listing Testing for DWGD

DWGD-ZC is listed under both UL 1978 standard and UL 2221. Products must pass two rigorous tests to obtain UL 2221 listing. First is an internal fire test, introducing flue gases to the duct at a temperature of 2000 degrees F for 30 minutes. While the sweltering gases are inside, the temperature of the exterior are measured and cannot exceed a certain temperature threshold.

An external fire test is the second requirement to become UL 2221 listed. This test simulates a building fire engulfing the ductwork. Trial two puts the duct in an oven for 2 hours with temperatures as high as 2,000 degrees F and the ductwork must maintain its integrity. Then the tested piece of ductwork is sprayed with a firehose immediately after being exposed to the fire test for 2 hours, causing thermal shock. Finally, the duct passes through a firestop and cannot exceed specific temperatures and cannot allow any water to pass through the firestop.

UL Listed in five categories:

- 1978 Standard, Grease Duct (ULC S662 Standard for Factory-Built Grease Ducts)

- 103 Standard, Building Heating Appliance Chimney (Industrial Type 540°C Chimney)

- 103 Additional Positive Pressure Listing to 90″ W.C.

- 2221 Standard Fire Resistive Grease Duct Enclosure Assemblies

- 103 Additional Type HT Listing

Ease of Installation

DWGD incorporates fast and easy connections with durability. Additionally, attached to each length of duct is a locking vee band connection. This eliminates requiring additional pieces for the installation of other ductwork options. DWGD pieces are available in a multitude of sizes, allowing for ultimate field flexibility and shortened installation time. Also, the DWGD-ZC model eliminates the need for supplementary fire-rated shafts. The joints are high pressure and leak-tested, so there is no need to worry about them once installed. Perfected factory pressure calculation is attainable in real-world installations due to smooth flow and known resistance. Finally, the DWGD eliminates the necessity for fire dampers in laundry, fume venting, and HVAC ducts.

Contact your SVL Sales Team to learn more about Jeremias’ Double Walled Grease Ducts, or click here.

Learn More About Jeremias or Contact Our Sales Engineers