AQC Dust Collecting Systems Dust Collectors

Horizontal Cartridge Dust Collector

Dust Collection

For More Information:

Vertical Cartridge Dust Collector

Dust Collection

For More Information:

The VC type dust collectors have been added to the horizontal line of cartridge collector. This product will serve in higher concentrations of dust applications with larger particulates. The vertical arrangement of the cartridges makes for a more efficient cleaning of the filters when large particles are filtered.

The MAXIFLO-VC is an up-flow enclosed type dust collector. These dust collectors are the ideal medium concertation dust and can be used with different dusts such as welding smoke, metal sanding, grinding or buffing, plasma, laser downdraft cutting tables, sandblast rooms operation, light to medium sized dry powders, food and pharmaceutical plants or plastic and composites fabricating shops.

- Costume made for various air volume capacities

- Multiple cartridge selection

- Automatic cartridge cleaning by pulsed air

- Interior or exterior installation

- Multiple dust storage configurations

- Wide selection of inlet and outlet locations

- Minimal field assembly required

- Fully welded cabinet

- Many different accessories available to meet NFPA and other regulations

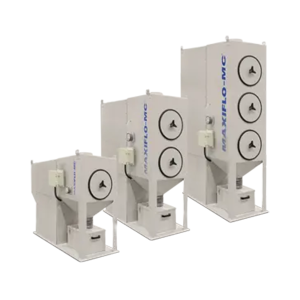

Pleated High Efficiency Cartridge Dust Collector

Dust Collection

For More Information:

Cartridge collectors are designed for a wide range of particle filtration. Using the same technology as the regular and larger MAXIFLO units, the MAXIFLO-MC has the advantage of being installed quickly and easily. Shipped fully assembled and taking very little space, the unit can be in service rapidly. The quiet motor-fan assembly with anti-spark polyamide backward inclined impeller allows great air volume and medium to high static pressures.

The integrated control panel ensures constant and reliable cleaning of the cartridges by air pulse. Efficiency of cartridges may allow recirculation of filtered air into the premises. Maintenance is a snap by only emptying the dust storage bin. Safety features such as NFPA explosion relief venting doors or sprinklers may be added to the unit to comply with norms and standards.

- Modular for various air volume capacities

- Multiple cartridge selection

- Automatic cartridge cleaning by pulsed air

- Interior or exterior installation

- Heavy duty cartridge support yokes

- Minimal field assembly required

- Fully welded cabinet

- Many different accessories available to meet NFPA and other regulation

Multiple Pocket Shaker Type Dust Collector

Dust Collection

For More Information:

Designed for various air volume applications and solid particles filtration, the MAXIVIBE shaker dust collector is ideal for small to medium size shops and industries, training facilities or vocational schools. The narrow footprint of the MAXIVIBE unit means that it may be installed inside or outside of the facility without losing valuable floor space. The efficient envelopes with stitches allows clean air to be recycled back into the premises for maximum energy savings. The manual or motorized cleaning systems dislodge particles from the filter and are then stored in a variety of bins, drawers or drums. Safety features such as explosion relief vents, back draft dampers or spark detection and extinguishing systems for explosive or combustible dust are available.

- Pocket type filter efficiency of 95% to 99% at 1 to 5 microns

- Modular for various air volume capacities

- Automatic or cleaning shaker system

- Rugged painted steel cabinet and structure

- Powerful 1 H.P. motor for shaker mechanism

- Low or high profile dust storage system

- Dust inlet with abrasion resistant features

- Choice of interior or exterior installation

- Minimal field assembly required

Economical Pocket Type Manual Shaker Dust Collector

Dust Collection

For More Information:

Based on the MAXIVIBE design, the MAXIPLY manual shaker dust collector is economical since it does not need an enclosed cabinet and the cleaning system is performed by manually shaking the filter envelope. The efficient filter pocket envelope allows clean air to be recycled back into the premises for maximum energy savings. Primarily developed for interior installation in small shops and vocational schools, its use is perfect for medium to large size pollutants such as sawdust, grinding, buffing or sanding of wood.

Air volume capacity can vary from 500 CFM to 5000 CFM. The satin interior coated filter helps to minimize dust caking on filter surface. The angled hopper ensures constant sliding of pollutants into the dust storage drum. The support structure can be easily dismantled for relocation into another part of the facility or for a new installation in a room with limited size doorways.

- Pocket type filter efficiency of 95% to 99% at 1 to 5 microns

- Modular for various air volume capacities

- Manual cleaning shaker system

- Rugged painted metal structure

- Low or high profile dust storage system

- Dust inlet with abrasion resistant feature

- Minimal field assembly required

MAXIHYDRO

Dust Collection

For More Information:

In addition to their major advantages, MAXIHYDRO has no internal moving parts, no screens, no spray nozzles, no pumps. There is nothing that can break down, clog, or wear out. As a result, no maintenance is required, other than the simple removal of collected dust sludge. This reduces fan power requirements and saves energy. With explosive dusts and powders such as magnesium, aluminum, titanium, and other explosive materials, MAXIHYDRO units are safe to be used inside the workplace. Clean air can be discharged back into the plant providing great savings in power requirement, ductwork, required air make-up, and reduction of heating or cooling costs.

- Compact design for specified air volumes

- High collection efficiency for a given pressure drop

- Capability of handling varying dust loads without any change in the collection efficiency

- No mechanical parts can wear out and no spray-producing equipment can clog

- No horizontal metal surfaces where dust and sludge could collect and reduce air flow

- No water loss during operation other than by evaporation

- Automatic water compensation system

- High-efficiency mist eliminators

- Complete and easy access for routine cleaning and inspection

- Several methods of sludge disposal, including manual and mechanical methods

Baghouse Dust Collector

Dust Collection

For More Information:

The MAXITUBE dust collector is a bag house type dust collector featuring a large selection of alternative filter bags or pleated bags capable of solving any special dust application. Dust particles are drawn into a velocity reduction chamber adjacent to the filter section where large particles separate from the airstream to fall directly into the hopper; smaller particles are then drawn into the filter section and are filtered. This type of dust collector is usually medium to large in size and can handle tremendous air volumes and dust loads. The MAXITUBE is composed of tubes, also called ‘’socks’’ which vary in lengths. With the MAXITUBES filtering system, clean air can be recycled back into the premises for maximum energy savings. Maintenance is greatly reduced since the electronic pulse control sends a cascading signal to air valves pulsing compressed air from the inside of the bags to the outside forcing the accumulated dust cake to be blown away and fall into the hopper, all this while the collector is in operation. Baghouse collectors are generally installed outside because of their size and weight.

The maxitube is mainly used for sand blast rooms, wood transformation shops, chemical industries, mines, metal industry and food or pharmaceutical industries.

- Vertical felt or pleated bag for maximum efficiency

- Micronic dust size filtration

- Filtered air recycled back into premises for energy savings

- Large amounts of dust storage capacity

Cyclone dust collectors

Dust Collection

For More Information:

MAXICLONE cyclone dust collector use centrifugal energy to separate large and medium size particles from the air. The spiraling effect brings those particles towards the bottom of the cyclone and into a dust storage system. Clean air is then drawn upward into the inner cylinder and discharged into the atmosphere or into an after-filter system for additional filtration efficiency. Clean air can then be recycled back into the facility for maximum energy savings. The narrow footprint of the cyclone dust collector allows interior or exterior installation without losing valuable floor space.

- Minimal field assembly

- Minimal footprint

- Spinning cyclonic effect on large particles

- High efficiency

- Can be connected to a dust collector

- Ideal for wood, plastic or metal transforming industries