SVL News

Ventum ERV from Oxygen8 is Here to Help Cut Energy Costs

The All-New Ventum ERV Controls Humidity Levels While Cutting Operational Expenses

The new Oxygen8 Ventum HRV and ERV are now available. This energy-efficient, all-electric energy and heat recovery unit has the engineering to impress and maintains Oxygen8‘s mission of contributing to healthier buildings.

The new Oxygen8 Ventum HRV and ERV are now available. This energy-efficient, all-electric energy and heat recovery unit has the engineering to impress and maintains Oxygen8‘s mission of contributing to healthier buildings.

Ventum ERV Expands Efficiency

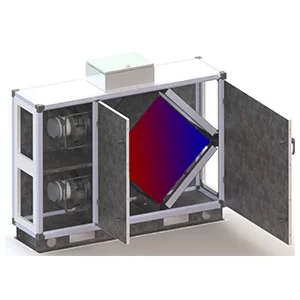

The Ventum has insulated panels, a variable-speed plenum, and ECM direct-driven fans with low energy consumption for high efficiency. Its counter-flow core allows for high sensible and latent energy recovery without air cross-contamination or moving parts. The unit’s internal bypass option provides free cooling between peak and off-peak seasons. Not to mention, these features provide excellent energy efficiency with Oxygen8’s known reliability.

Ventum ERV is All-Electric Powered

Ventum ERV units are all-electric ventilation solutions. They help to reduce the environmental effect of buildings while injecting 100% fresh outside air into the space. Outdoor air is a must when planning for optimal indoor air quality (IAQ). Furthermore, Ventum complements Daikin’s VRV Outdoor Unit for humidity and temperature control year-round. This energy-efficient, all-electric ventilation option provides savings on expenses long term.

Low Profile for Design Versatility

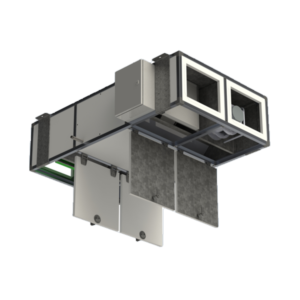

Ventum ERVunits have an 18 – 32” depth and 325 – 3000 cfm range. They are designed to be installed on each floor of a building. Consequently, the Ventum reduces space requirements, making it an attractive option since space is often at a premium in mechanical rooms and rooftops. The decentralized indoor ventilation also adds floor space by doing away with vertical duct runs. Correspondingly, Oxygen8’s Ventum needs only a minimal footprint to provide superior ventilation and improved indoor air quality.

User-Friendly Intelligent Controls

The Ventum’s intelligent control panel can operate independently or be seamlessly integrated into BMS, with more than 75 built-in functions. Some of those functions include:

- Discharge air temperature

- Humidity control

- Weekly schedules

- Economizer

- Dirty filter alarms

These easy-to-use controls help facility managers fully customize their ventilation preferences.

About Oxygen8

Oxygen8 is committed to reinventing how healthy and comfortable air is delivered to building occupants in an energy-efficient way. It works to enhance work and living environments with completely fresh filtered air. Coupled with smart technology, Oxygen8 can provide ultimate comfort and value.

The Importance of Oxygen

Oxygen8 (ox·y·gen·ate)’s name is not just a play on the term. The company’s goal starts with excellent ventilation to provide building occupants with 100% fresh air. Quality indoor air invigorates building occupants and helps to reduce absences, illness and increase alertness. Oxygen is also the eighth element on the periodic table.

Oxygen8’s Objectives

Occupants are becoming ill while learning in schools, working in offices, and convalescing in elderly care facilities. Typical HVAC systems are centralized and recirculate air with inadequate humidity and filtration. These factors are often the cause of poor IAQ. Prevention is key to lowering the transmission of bacteria, viruses, and other contaminants. Likewise, new HVAC systems need to supply dedicated outside air and eliminate recirculation to best achieve this objective. Together with HEPA filters, controlled humidity levels, ERVs can help to eliminate contaminant crossover.

Greenhouse gases are another thing to consider when making efforts to improve IAQ. Multiple cities across the United States, Canada, and Mexico are working toward net-zero energy buildings in the next ten years. This initiative will continue to drive demand for efficient, fully electric HVAC systems. Oxygen8 has this in mind and is developing products to meet this need.

Finally, improved building design is a priority for Oxygen8 when thinking about the facility’s future and changes to HVAC standards. Super-insulated facilities can drastically reduce heating requirements. Developer’s designs containing large windows and climate change will increase the need for cooling in the future. Integration of VRVs with ERVs will help to reduce energy use and meet the ever-changing ventilation requirements for years to come.

Learn More About Oxygen8 or Contact Our Sales Engineers