SVL News

- All

- Company News

- Products

- SVL Seminars

Hurst Boilers: Upgrade to Superior Efficiency with Custom Hot Water and Steam Boilers

Matt Whittington from Hurst Boilers updated us on Hurst’s class-leading efficiency. Hurst has optimized heat transfer in their hot water and steam boilers. Matt Spotlights their different Scotch Marine offerings.

Accutrol: The Technological Revolution in Critical Airflow

Accutrol has seen the desire for energy efficiency and flexibility in critical airflow control. They provide premiere Critical Airflow solutions.

INTEC: The Premier Gas Detection Solution

Headquartered in San Diego, INTEC Controls has been a supplier of high-quality sensors and controls for commercial HVAC for over 30 years. Jennifer gave our attendees a deep dive into the current state of CO and NO² detection systems.

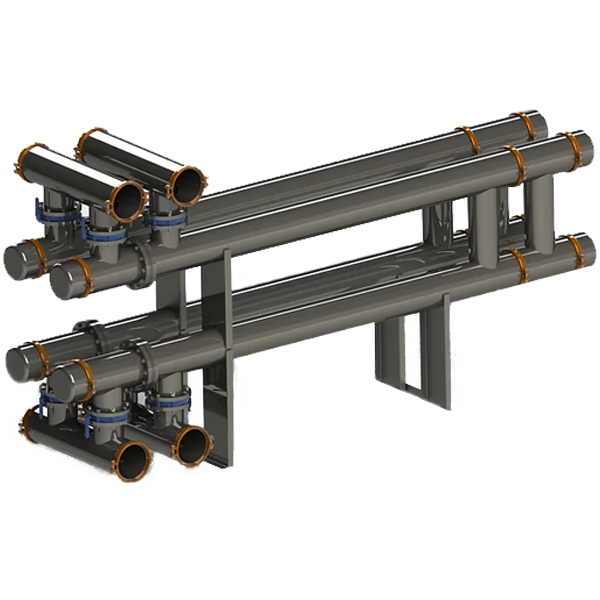

Armstrong: Reduce Operating Costs by up to 30% with Parallel Pumping Technology

The design strategy you choose for hydronic pumping arrangements will affect both your installed first costs and energy costs over time. That was the message from Tony Furst, director of applications engineering for Armstrong Fluid Technology, at a recent Coffee Break webinar.

Fulton Boilers: Innovative Heat Transfer for a Sustainable Future

How do we best ensure sustainable indoor air quality and energy-efficient air handling? Oxygen8 High-Efficiency DOAS Systems solve this.

Lisa Grissman, Welcome to the SVL Team

SVL is excited to introduce Lisa Grissman, our new billing clerk and dispatch coordinator. Lisa has been with SVL since September and…

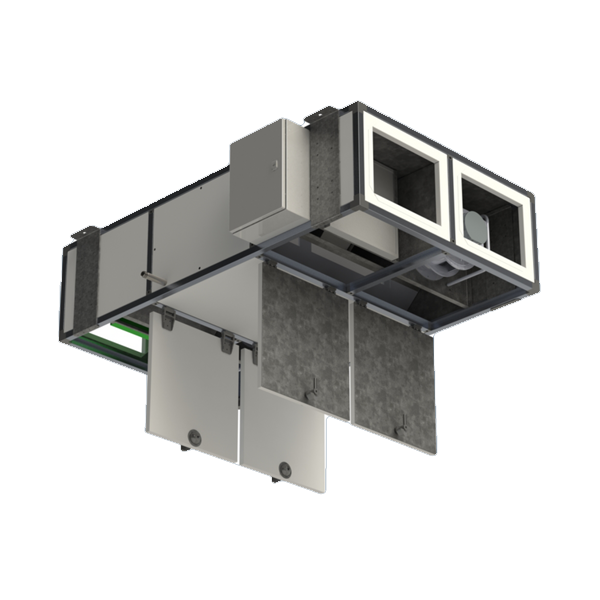

Oxygen8: High-Efficiency DOAS Systems

How do we best ensure sustainable indoor air quality and energy-efficient air handling? Oxygen8 High-Efficiency DOAS Systems solve this.

Tom Wilwert, Welcome to the SVL Team

SVL is excited to welcome Tom Wilwert, our new vice president of data center solutions. He will be instrumental in growing our data center business nationwide.

GPS: Improving IAQ and Mitigating Wildfire Smoke

We sat down with Peter Eno from GPS, who described the company’s technology and its applications for viewers of our most recent Coffee Break webinar.

Welcome to our Newest Interns, Mike Overbo and Ben Hogan!

We’d like to take a moment to recognize two SVL interns who have done exemplary work for us this summer — Mike Overbo and Ben Hogan.

enVerid: Innovative HVAC Load Reduction Modules

We recently sat down with Matthew Gundrum from enVerid as he explained how the company’s Sorbent Ventilation Technology (SVT) is changing how engineers design air delivery systems.

Mike Swanson, Welcome to The SVL Team

SVL is excited to welcome Mike Swanson, the newest aftermarket specialist on our world-class SVL Parts team.

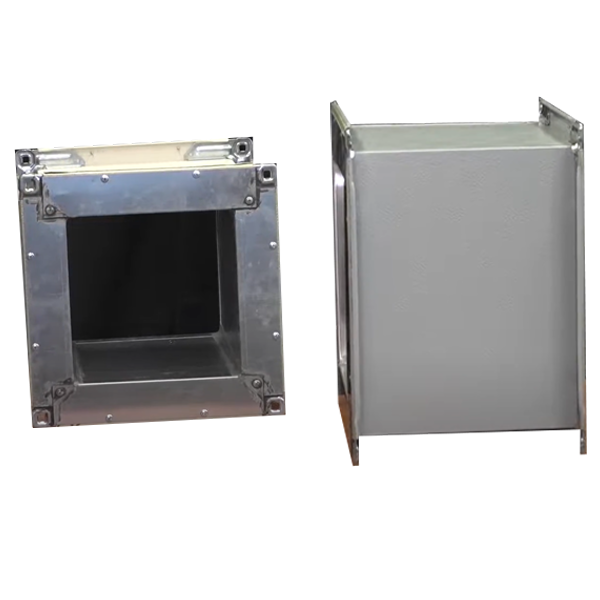

Pro-R: High-Performance Outdoor Duct System

Our Coffee Break series hosts the brightest minds in HVAC discussing the revolutionary High-Performance Outdoor Duct System from Pro-R Duct

High-K Heat Exchangers: No Downtime During Maintenance

High-K Heat Exchanger feature a shell-and-tube construction with a true counter-flow design for effective heat transfer. Learn more from SVL

Rebecca Glenn, Welcome to the SVL Team!

SVL is excited to introduce Rebecca Glenn, our new Administrative and Events Coordinator. Rebecca has been with SVL since early March 2023…