Heat Pipe Technology Energy Recovery - Split Passive

Heat Pipe Technology HRM-V™

Dehumidifier Heat Pipes

For More Information:

The HRM-V Split Passive Series of energy recovery heat pipes are compact and highly efficient heat transfer devices. They recover energy in process applications and from exhaust air to pre-cool or pre-heat outdoor air in comfort applications without cross-contamination.

Unique to heat pipe thermo-siphon systems, this technology gives the design engineer a lot of flexibility and, more importantly, ZERO cross-contamination. And, unlike a water run-around, it comes with higher effectiveness, no moving parts, and better efficiency.

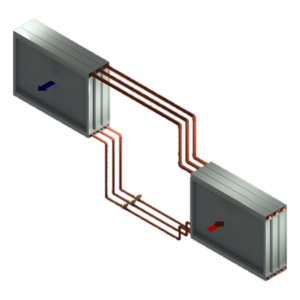

Split Passive Series Design

A typical system comprises three circuits, and each circuit combines two rows of heat exchangers. Each circuit has a vapor header at the top end and a liquid header at the bottom.

With a permanent elevational difference between supply and exhaust air streams, HPT optimizes the unit for the season that yields the most BTUs. In the lesser season, and depending on elevational difference, some recovery will also occur, but far less than in the more dominant season. In Minneapolis, for example, that would be the heating season, and the opposite would be true for Phoenix, Arizona.

Control valves are usually added and located on the liquid side of each circuit. When open, full recovery is taking place; when shut, no recovery is taking place.

Winter-Only

- Higher single-season (winter) recovery

- Maximum 120-foot pipe length

- Elevation at least + 25% of section FH

- Moisture eliminator or extended drain under exhaust coils

- Typical effectiveness: 50%

- AHRI-certified performance to std. 1060 and ETL listed

Summer-Only

- Higher single-season (cooling) recovery

- Maximum 120-foot pipe length

- Elevation at least + 25% of section FH

- Moisture eliminator or extended drain under supply coils

- Typical effectiveness: 45%

- AHRI-certified performance to std. 1060 and ETL listed

Winter and Summer Recovery

When supply and exhaust coils are on the same level, and summer and winter recovery are equally important, utilize an HRM-V with a Dynamic Seasonal Offset (DSO™). This system will yield equal cool and heat recovery with 45% effectiveness on average when used in a 6-row system and 500 fpm air velocity. The remarkable design of this HRM-V™ product optimizes energy recovery performance by 20-35% over older side-by-side (no offset) designs.

The unit achieves optimized performance by using integral face dampers to direct flow through sections of the heat pipes to create an offset effect, thus enhancing performance. A single heating/cooling changeover signal controls the dampers, always keeping the condenser side of the heat pipes higher than the evaporator.

- Balanced heating/cooling recovery

- Maximum 120-foot pipe length

- Supply and exhaust at the same level

- Moisture eliminator or extended drain pan required under supply and exhaust

- Integral face dampers create an offset effect

- Typical effectiveness: 45% summer and winter

- AHRI-certified performance to standard 1060 and ETL listed