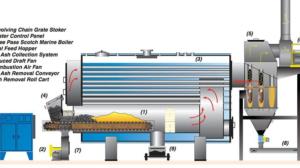

Hurst Boiler - Solid Fuel Fired

Coal Fired Boilers

Solid Fuel Fired Boilers

For More Information:

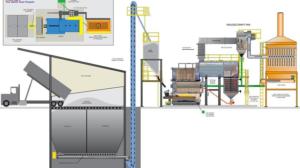

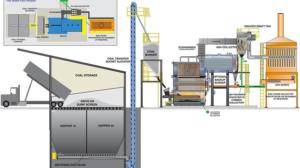

Hurst Boiler provides its clients with the support and expertise necessary to design, fabricate and install complete solid fuel boiler systems, from the fuel storage system thru exhaust gas emission mitigation. Various Boiler designs are suitable for applications to produce high pressure steam or hot water in ranges from 3,450 – 60,000 lbs/hr (3.4 mmBTU – 60 mmBTU) output from 100 up to 900 PSI.

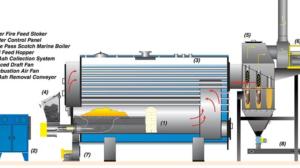

Wood Fired Boilers

Solid Fuel Fired Boilers

For More Information:

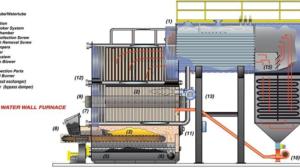

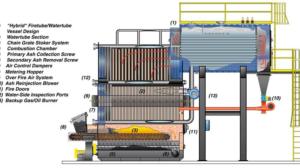

Hurst Boiler provides its clients with the support and expertise necessary to design, fabricate and install complete wood boiler systems, from the fuel storage system thru exhaust gas emission mitigation. Various Hybrid Wood Boiler designs are suitable for applications to produce high pressure steam or hot water in ranges from 3,450 – 60,000 lbs/hr (3.4 mmBTU – 60 mmBTU) output from 100 up to 900 PSI.

These systems are designed by HBC to combine the best technologies from the “old school” of biomass combustion and the latest new technologies of advanced combustion control.

The boiler vessel in each of these systems is a two pass hybrid design incorporating a water tubed boiler-type water membrane and a two-pass fire tube scotch marine vessel. These boilers advantages over standard water tube boilers include a much larger steam disengagement area providing high quality steam, larger steam storage capability for quicker response to sudden steam demand, and much larger thermal storage that provides fast demand response times and safer operation.

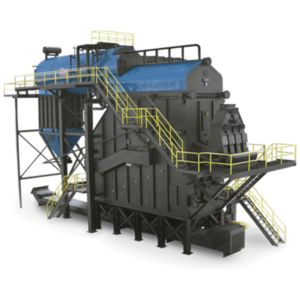

Biomass Boiler Systems

Solid Fuel Fired Boilers

For More Information:

Biomass-Fired Steam Boilers, Hot Water Boilers and Direct-Fired STAG units for Solid Fuel Systems

Energy solutions based on biomass and bio-fuels provide clean and renewable energy for large national and international companies. Green-thinking companies are now using biofuels to mitigate the impact their activities have on the environment by reducing emissions of greenhouse gases. This can also generate earnings for your company by saving money on energy costs, and by the sale of carbon credits. Achieve energy independence, get off the Gas Grid, and no longer be at the mercy of the oil markets. Hurst Boiler is a leader in the development of boiler technology and energy management projects through sustainable solutions for renewable energy and energy efficiency by biomass. HURST Biomass, Gasification and Gasifier Boiler Systems will strengthen your bottom line by reducing, or even eliminating your energy and disposal costs altogether, through the combustion of renewable fuel sources, also known as Biomass.

Consider trading fossil fuels for agricultural biomass, wood, bark, agave fiber, rice husk, chicken manure, sugar cane bagasse, king grass, MSW, construction debris, nuts, shells, husks, paper, card/board products, hog fuel, sawdust, shavings, and/or sludge. Alternative Fuel Solutions and Hurst packaged projects can help you reduce carbon, reduce emissions, and reduce both operating and fuel costs, as well as being eligible to sell your carbon credits.

Hurst Boiler provides its clients with the support and expertise necessary to design, fabricate and install complete solid fuel boiler systems, from the fuel storage system thru exhaust gas emission mitigation. Various Boiler designs are suitable for applications to produce high pressure steam or hot water in ranges from 3,450 – 60,000 lbs/hr (3.4 mmBTU – 60 mmBTU) output from 100 up to 900 PSI.

As the overall market sets on the path of environmental sustainability and energy costs continue to increase, industry leaders will be hard pressed to find economically viable solutions to stay ahead of the curve. Profiting from the implementation of energy efficient and sustainable technology will be necessary to maintain a competitive advantage. Hurst Biomass Boiler Systems provide successful strategies and technology which can reduce the operational costs of current facilities and provide an ROI from installation in new construction.

Energy Efficient & Environmentally Sustainable Building Technologies using Biomass

Let Hurst Boiler help you implement the next generation of technologies in todays facilities. Discover how to obtain immediate benefits from current environmental initiatives. Take advantage of environmental and energy reducing strategies in new construction and retrofit projects. These are just some of the latest developments in Biomass Boiler Technology that Hurst can provide to benefit your business and your bottom line!

Sustainable Operations Green Retrofit & Construction

- Integrating sustainability initiatives in your business model

- Establishing performance metrics and benchmarking programs to quantify results

- Selling the ROI and competitive advantage gained from sustainability programs

- Measuring efficiency through the implementation of environmental management systems

- Waste reduction and risk management

- Successful programs to reduce water usage in facilities

Objectives, Strategies and Implementation in:

- Profitable implementations of Biomass, CHP and other co-generation technologies

- Corporate strategies to reduce overall facility operating cost in new development

- Tackling excess energy expenditures in HVAC, Lighting and legacy equipment

- Implementing LEED and Green design principles from the onset of new construction and retrofit projects to achieve higher cost savings

CHP/CHCP: (Combined Heat and Power/Combined Heat, Power and Cooling):

- Engineering and Design for utilizing and implementing Combined Heat and Power (CHP)

- Specifications for Turbine, Steam GenSets, and ORC (Organic Rankine Cycle) Equipment and Technologies

- Competitive advantages of CHP/CHCP applications for the coverage of energy demand (i.e. electricity, heat and cooling) in the industrial and commercial sectors

- Permitting, regulatory and grant information and guidance

Energy Management:

- Creating an overall strategy for applying cost effective renewable energy technologies

- Reduction of risk and expenditures on energy in your operations

- Ensuring the reliability of your energy infrastructure as new equipment is implemented

- Maximizing the benefits of renewable energy credits, offsetting and government programs

- Learn more about HURST Biomass Boiler Systems and see models and plan views, click here.

Elimination of Biomass Emissions

Generally speaking, the combustion of biomass material produces emissions that can prove to be undesirable. Maintenance is typically also an issue with regular tube-cleaning and ash removal. HURST has virtually eliminated those potential undesirables through engineering, and a proven system.

Hurst Boiler & Welding Co., Inc manufactures its biomass boiler systems with an extended burn chamber, increasing dwell time for the combustion of any unwanted particulates and emissions before they are able to exit the system, making the process much cleaner, which reduces maintenance time and costs.

Through the effective use of combustion air, a HURST system is capable of burning material with 0-50% moisture content. In fact, the Primary Combustion Zone reaches temperatures as high as 1850°F.

Automated Ash Removal

This system removes the ash from the unit automatically into self-contained ash bins, allowing for continual operation; thus, eliminating costly downtime and unnecessary labor and operational costs. In addition, its hands-free operation, makes the system much safer.

Cast Refractory Ceramic Lining

HURST Biomass Boiler Systems are equipped with high temperature cast refractory ceramic lining for longer life. This cast refractory/ceramic lining was designed to be completely modular, which makes for easy repair and replacement.

PLC Controls

The HURST PLC Control System is one of the most advanced systems available for biomass combustion in today’s market. The Control Panel is fully automated and continually monitored via a Programmable Logic Controller. The air flows and fuel feed rates are constantly and automatically adjusted by way of variable frequency drives to ensure a hot water or warm air temperature that is maintained within 3 to 5 degrees of the desired set point. Fuel feed motors, combustion fans, and the induced draft fan all run on variable frequency drives to ensure the proper mix of combustion air to fuel. The unit adjusts itself automatically according to load demand. The system can also operate on “Maximum Fuel Consumption” Mode to utilize the capabilities of the specific burner and combust as much fuel as possible. All controls and monitoring of the system are accessed via 10-inch color touchscreen monitor located on the front of the main control panel.

Solid Fuel Burners

Solid Fuel Fired Boilers

For More Information:

Industrial grade wood-fired burner with HURST “clean-burn” stoker design. Modular packages available from 5 MMBTU/HR – 250 MMBTU/HR with operating temperature ranges from 200°F to 2000°F. These proven solid fuel burner systems are a leading choice in lumber dry kilns, boiler applications, oil heaters, rotary dryers, brick kilns, and more. Hurst manufactures seven different types of biomass stoker/gasifiers, which have used 2,000+ different types of biomass fuels. With installations across all industries worldwide, Hurst is recognized for the highest code standards, innovative engineering and design, Energy Star rating, and renewable, sustainable solutions for green building design and operational efficiency.

Our Hurst “STAG” systems are a culmination of our experience and knowledge of material handling, solid fuel combustion, and controls integration that offers a quality solution for most air heating applications. We are providing our customers the ability to economically and efficiently satisfy their air heating requirements by utilizing readily available waste as a fuel source in lieu of the expensive conventional sources. Hurst delivers the quality and performance that our customers expect in a custom engineered solution to reduce operating expenses and maximize productivity.

The Hurst STAG unit can be utilized from 5 MMBTU/HR – 250 MMBTU/HR with operating temperature ranges from 200°F to 2000°F. These systems are frequently utilized in lumber dry kilns, boiler applications, oil heaters, rotary dryers, brick kilns, and much more.

Rotary Dryers • Sand Dryers • Grain Dryers

Lumber Kilns • Cement Kilns • Brick Kilns

Reciprocating Grate Design – Complete burn with automatic dust-free wet ash removal system.

Modular packaged design for low cost project installation.

Twin Unit– Southern Pine Sawmill Lumber Dry Kiln

EQUIPMENT FEATURES

- totally automated system

- Superior refractory material

- Automatic ash removal system (wet & dry systems)

- Ash sifting hoppers

- Unique wall/grate interlocking discourages internal fuel leakage

- Reciprocating Grate Design – Complete burn with automatic dust-free wet ash removal system.

- Modular Packaged Design for low-cost project installation.

BIO-MASSter Boiler and Integrated Combustion Control/Monitoring System HURST BIO-MASSter is one of the most advanced systems available for controlling biomass combustion and boiler operation. Our expertise combined with our commitment to improvement has allowed us to develop a biomass boiler and control system unsurpassed in the biomass industry. The system is fully automated and provides ultimate control and flexibility to meet the requirements of various biomass fuels. In addition, our product line includes Flat Grate, Underfeed, and Traveling Grate Stokers to meet any biomass burning requirement.

Biomass and bio-fuels provide a clean and renewable energy solution. Many green-thinking companies are using bio-fuels to:

- Manage their impact on the environment

- Reduce emissions of greenhouse gases

- Cut energy costs

- Generate revenue by the sale of carbon credits

- Achieve energy independence

- Reduce or eliminate waste disposal costs by using it as fuel

Hurst Boiler is a leader in the development of boiler technology as well as sustainable solutions for renewable energy.

Offering integration and scalability, the new, high-efficiency Integrated Control Systems from Hurst Boiler for boiler room monitoring and communications provide advanced supervisory boiler controls for all new and legacy Hurst products.

BIOMASSTER

Firing boilers on solid fuels has always been a challenge. With variables like fuel-moisture percentages and varying BTU values, achieving a constant and clean burn with solid fuels can be cumbersome at times.

The Biomasster system is designed as a complete monitoring and automated control system providing intuitive control of the boiler, fuel feed, and peripheral equipment operation. Through the HMI (human-machine interface), the operator is given a “dashboard” view of all the motors, devices, and processes relative to easy operation of the boiler. From the main operator’s view, all points of the system are visible and easily accessible.

All Hurst solid fuel customers can upgrade to this new technology. The Biomasster system is easily adapted to any existing Hurst solid fuel boiler system.

Imagine the ease and lower cost of operation once this system is working for you.